**What is a Boiler Room?**

In response to the question of what a boiler room is, it can be said that a boiler room in residential, office, commercial, or industrial buildings is a room or space designated for housing the equipment and components of the boiler room (mechanical and electrical systems for cooling and heating). The size of the room or space is proportional to the dimensions and scale of the building or industry in question. In smaller buildings or industries, a single room in the lower floors is usually sufficient for installing boiler room equipment. However, in large residential, office, commercial, or industrial buildings, multiple rooms or one or more floors are often allocated for the installation of boiler room components.

**Key Components of Boiler Rooms in Buildings and Industries**

The components of boiler rooms in buildings and industries include:

1. **Equipment for Generating Hot and Cold Water**

1.1. **Boilers:** Also known as hot water or steam boilers with gas burners (devices for heating water) with efficiency between 78% and 86%.

1.2. **Chillers:** Devices for cooling water.

1.3. **Cooling Towers:** Installed in open spaces like roofs or yards (if using a water-cooled or absorption chiller).

*Note: Air-cooled chillers do not require cooling towers.*

2. **Equipment for Generating Domestic Hot Water**

– **Hot Water Storage Tanks:** Includes double-walled tanks or coil tanks (for drinking water and washing).

3. **Ancillary Equipment**

3.1. **Expansion Tank**

3.2. **Sand Filter and Water Softener:** Tanks for removing hard minerals from the water and preventing them from reaching the boiler.

3.3. **Electrical and Control Equipment:** Such as electrical panels, sensors, solenoid valves, central processors, flame regulators in boilers (according to consumer needs), and optimization control systems for chillers.

3.4. **Other Boiler Room Equipment:** Includes valves, secondary pipes, insulation, fire water pumps, etc.

4. **Systems for Transporting Hot and Cold Water to the Building**

4.1. **Hot and Cold Water Circulation Pumps**

4.2. **Pipes, Collectors, and Main Distribution Valves**

5. **Devices for Distributing Hot and Cold Air in the Building**

– Use of equipment such as fan coils, radiators, air handlers, etc., for distributing hot and cold air inside the building (through heat exchange between hot and cold water and air in these devices) or sending cold water to industrial equipment for cooling in factory boiler rooms.

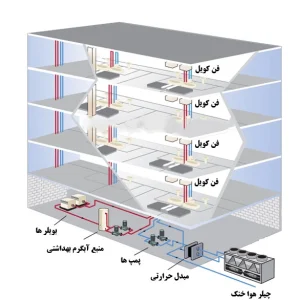

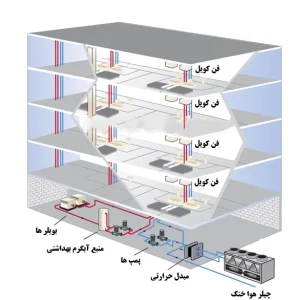

The image below shows a simple example of the key components of a building’s boiler room, including a chiller, boiler, domestic hot water tank, and fan coils on each floor for air conditioning (cooling and heating).

Important Points About Industrial and Building Boiler Rooms:

Maintenance and Operation:

Equipment and components in large boiler rooms are typically maintained by a resident engineer or technician.

Modern boiler room components are controlled by advanced control systems that interface with other building control systems, such as lighting and safety systems.

Electrical and electronic equipment is usually not installed in the boiler room but placed elsewhere.

Design Considerations:

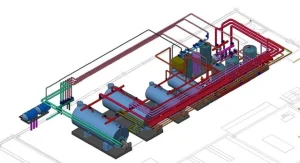

The key issue in designing a boiler room is to achieve maximum efficiency while minimizing equipment and complexity. This is typically done using specialized design software like Revit MEP and PDMS.

Domestic hot water is produced using heat exchangers (coil tanks) or double-walled tanks.

How Does a Boiler Room Work?

A boiler room operates by using water-cooled or absorption chillers to reduce the temperature of the incoming water and gas-fired boilers to increase the temperature of the water. Pumps then distribute this hot and cold water through a central piping system to various parts of the building for heating or cooling (via radiators, fan coils, air handlers, underfloor heating systems, etc.) or to industrial equipment for cooling.

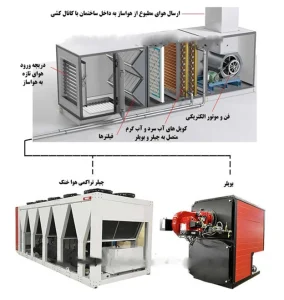

In the image below, an example of an air-cooled chiller and boiler is shown, which sends cold and hot water to the air handler installed on the roof. The fan in the air handler adjusts the air temperature by blowing air over the cold or hot water pipes, distributing the conditioned air throughout the building.

Complexity in Large Boiler Rooms:

The number of pipes, valves, and pumps in large industrial or building boiler rooms can be overwhelming, especially for those unfamiliar with their operation. In essence:

Chillers are water-cooling devices.

Boilers are water-heating devices.

Hot and cold water are distributed through pumps and pipes throughout the building.

Hot water for drinking and washing is produced in a domestic hot water tank (double-walled or coil-type). Hot water or steam from the boiler is pumped into the tank, where it exchanges heat with a municipal water line, increasing the temperature of the domestic hot water. This water is then distributed throughout the building for daily use.

Design Considerations for Central Systems:

Central Pumps for Cold Water Distribution:

Pumps move chilled water to equipment like air handlers and fan coils. Balancing flow can be challenging due to multiple circuits.

Separate pumps for primary and secondary circuits can help avoid flow imbalance issues.

Separate Flow Systems:

Ensure that control valves only experience pressure differentials from the secondary pump, not affecting the primary system.

Avoid serial connections between primary and secondary systems to prevent pressure issues.

System’s Highest Point:

Maintain positive pressure at the highest point of the system.

Use heat exchangers to manage pressure differences in tall buildings.

Economic Analysis of Piping vs. Pumping Costs:

Optimize water temperature to balance chiller efficiency and distribution system performance.

Equipment Arrangement:

Ensure adequate service space and accessibility for equipment and connections.

Advantages of Central Boiler Rooms Over Smaller, Multiple Systems:

Staffing Needs:

Centralized systems can reduce or eliminate the need for on-site operators.

Insurance Costs:

Lower due to reduced risk of fire or accidents from fewer boilers.

Useful Space:

Frees up space in the building for other uses.

Maintenance Costs:

Reduced due to fewer mechanical components.

Thermal Efficiency:

Central systems often have higher efficiency and better performance under varying loads.

Fuel Diversity:

Central systems can utilize multiple fuel types, including cheaper options like coal or waste.

Economic Aspects of Energy Source:

Considerations for temperature and pressure in new designs can impact cost-effectiveness.

Investment Savings:

Savings in initial investment costs through conceptual planning, design, construction, installation, and connection to consumers.

**8. Investment Cost Savings**

Generally, saving on investment costs is the primary economic factor in choosing a central cooling and heating system.

There are four stages to saving on initial investment costs:

**8.1. Conceptual Planning**

In conceptual planning, two aspects need to be examined: the technical and financial feasibility of the central cooling and heating systems.

**8.2. Design**

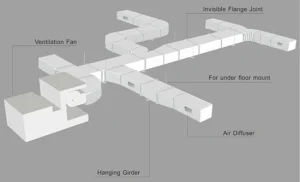

The distribution system constitutes a significant part of the initial investment. The design of the distribution system depends on the heat transfer fluid selected, its operating temperature and pressure, and the routing. To optimize the system’s insulation properties, a detailed analysis must be conducted to assess and analyze the economic thickness of the insulation for pipes and ducts.

**8.3. Construction and Installation**

The costs of constructing and installing a central facility and its distribution system depend on the quality of conceptual planning and design. Changes during construction typically increase final costs and delay commissioning. The time required for constructing central cooling and heating systems is usually determined by the time needed to order and procure equipment. In some cases, procuring the main components of central facilities can take over a year. The time needed to execute the distribution system also depends on the routing and intersections with existing facilities.

**8.4. Connection to Consumers**

High costs associated with connecting consumers to the distribution system may lead some to forgo connecting to the central cooling and heating system in favor of smaller boiler systems. For example, if a building is already equipped for steam service, connecting it to a central hot water heating system might be so costly (even if energy consumption costs are lower) that it is not economically justified.

What is a Smart Boiler Room?

A smart boiler room incorporates sensors and actuators to automatically reduce energy consumption and enhance occupant comfort. Smart boiler rooms differ from traditional ones in several ways:

Advanced Technology: Utilizes modern control technologies for efficient operation.

Remote Monitoring: Allows for real-time adjustments and monitoring.

In the image below, you can see the main equipment of a smart boiler room located in the building’s lower level. The air-cooled chiller (installed outside) and the gas-fired boiler (inside) work together to manage air temperature and domestic hot water supply, optimizing energy use and comfort.

**Structure and Differences Between Smart and Traditional Boiler Rooms**

The two main energy-consuming sources in boiler rooms are chillers and boilers. Chillers typically use electrical energy, while boilers use natural gas to heat water in the boiler and cool water in the chiller. This heated and cooled water is then pumped to consumer units such as air handlers and fan coils (for cooling and heating the air inside the building) and also to sanitary hot water systems for washing.

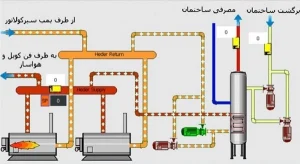

In the image below, you can see the main equipment of a boiler room located in the lower floor of a building. The chiller used in this system is an air-cooled compression type, which is installed outside the building (in the yard or on the roof). The cold water from the chiller (blue circuit) and the hot water from the boiler (red circuit) are pumped through pipes to the fan coils inside the building, where they perform the functions of cooling and heating the air.

In traditional (non-smart) boiler rooms, the control of the water temperature exiting these devices is managed manually by a thermostat, and the temperature of the outgoing hot or cold water remains constant.

In smart boiler rooms, numerous sensors are installed at various points inside and outside the building, as well as on the inlet and outlet pipes of these devices. All these sensors are connected to a central processor, which continuously receives temperature data signals.

The smart boiler room’s processor is connected to actuators that automatically adjust the burner fuel supply of the boiler or the operation of the electric motor connected to the chiller compressor based on the consumer’s needs and the climatic conditions. This ensures optimal operation to minimize energy consumption. For instance, if the outside temperature is -4°C, the gas burner flame of the boiler will be adjusted to achieve an output water temperature of 75°C; if the outside temperature is +4°C, the output water temperature will be 65°C.

Moreover, since the water temperature is precisely adjusted according to the consumer’s needs, the comfort level of the building’s occupants is maximized, and fluctuations in temperature at different times of the day are prevented.

Another advantage of smart boiler rooms is the reduced wear and tear on equipment due to optimized operation, which lowers maintenance and repair costs.

**Advantages of Smart Boiler Rooms for Non-Residential Buildings**

In non-residential buildings (such as industrial, commercial, educational, and administrative buildings), where cooling or heating is required only for certain hours of the day, the smart boiler room can be scheduled to operate weekly and monthly. This ensures that the equipment runs only during specified hours according to a user-defined schedule. Consequently, during off-hours, the equipment can either be turned off or set to standby mode to prevent energy waste.

A touch screen wall monitor is used in the smart boiler room system for monitoring temperatures in various areas, displaying the operation of burners and chillers in graphical form for performance analysis, intelligent fault diagnosis, and alerting the user in case of any faults or potential issues. Additionally, the system allows remote management via the internet and a mobile app, enabling the user to control, turn on, turn off, or adjust the equipment from anywhere.

In the image below, the most important electrical equipment for smart boiler rooms is illustrated.

**Modern Boiler Rooms**

Today, most of the latest generation boiler rooms are equipped with smart technology for the entire system. The foundation of these modern boiler rooms is the same as the previous equipment (boiler, chiller, pump, etc.), with the addition of advanced control systems and technologies. The chiller used in modern boiler rooms is typically a water-cooled, inverter-equipped chiller (with a variable-speed electric motor and compressor), while the boiler used is a burner-equipped unit with automatic control technology and efficiency-enhancing equipment. The image below shows an example of a modern boiler room.

**Designing HVAC Systems for Hospitals**

When designing heating, cooling, and air conditioning (HVAC) systems for hospitals, the needs of various departments are first assessed, and the most suitable equipment is selected accordingly.

Key sections of a general hospital include:

1. **Surgery and Intensive Care**

2. **Nursing**

3. **Auxiliary Spaces**

4. **Administrative Areas**

5. **Diagnosis and Treatment**

6. **Sterilization of Equipment and Supplies**

7. **Support Services**

It is crucial that during the design and construction of HVAC systems for hospitals, close coordination between the designer and medical equipment specialists is maintained to achieve optimal conditions.

**Design Criteria for HVAC Systems in Key Areas:**

1. **Ventilation for Surgery and Intensive Care**

No area in a hospital requires as precise control over environmental sterility as surgical suites. Systems used in operating rooms need specific designs to minimize the concentration of airborne pathogens.

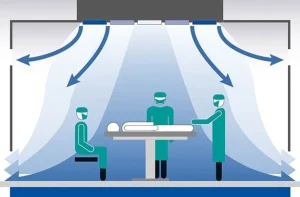

2. **Ventilation for Operating Rooms**

Studies of air distribution systems in operating rooms and observations from clean rooms in various industries indicate that the most effective air movement pattern involves supplying air from the ceiling and directing it towards multiple exhaust vents located on the opposite walls, as illustrated below. For the removal of anesthetic gases from the operating room, a dedicated air exhaust system or specialized vacuum system should be provided. Medical vacuum systems can be used for non-flammable anesthetic gases. Each operating room should be equipped with one or more vacuum ports to connect to various points for collecting and removing anesthetic materials.

The following conditions are recommended for operating rooms, as well as for procedures such as catheterization, cystoscopy, and fracture repair:

1. Temperature control within the range of 68 to 76 degrees Fahrenheit

2. Relative humidity maintained between 50 to 60 percent

3. Positive room pressure compared to adjacent rooms with 15% additional air supply

4. Proper sealing of all walls, ceiling, and floor

5. Suitable placement of thermometers and hygrometers

6. Use of air filters meeting standards

7. All air supplied from the ceiling and returned from at least two points near the floor

8. All equipment must comply with standard requirements

**3. Ventilation for Emergency Department**

The emergency department is often the most contaminated area of the hospital due to the high volume of patients and their accompanying persons, leading to a dusty and dirty environment. The temperature and humidity in the waiting area and administrative office of the emergency department should be maintained within comfortable ranges. For emergency operating rooms located near the emergency department, temperature, humidity, and fresh air levels should be similar to those in standard operating rooms. The storage room for anesthetic materials must be ventilated according to standards. Additionally, it is recommended to rely solely on mechanical ventilation.

**4. Ventilation for Intensive Care Unit (ICU)**

This unit houses critically ill patients, ranging from those recovering from surgery to patients with heart conditions. It is suggested that temperatures be variable within the range of 75 to 80 degrees Fahrenheit, with relative humidity maintained between 30% and 60%, and positive air pressure. Protective isolation units (PIUs) for patients with compromised immune systems (such as those with leukemia, organ transplants, bone marrow transplants, or severe burns) are highly susceptible to infections. Air changes should be considered at 15 times per hour. Sterilized air is drawn from above the patients and returned near the floor (near the room door). Using a separate air handling system for isolation units simplifies pressure control and improves air quality.

**5. Ventilation for Isolation Rooms for Infectious Patients**

These rooms are used to protect other areas of the hospital from the spread of contagious diseases. The presence of drug-resistant strains of tuberculosis increases the importance of air exchange, room pressurization, air filtration, and distribution in these rooms. The temperature and humidity in these rooms should be similar to those in patient rooms.

**6. Ventilation for Sterilization Areas**

Contaminated equipment and materials are brought to this unit for cleaning and sterilization before reuse. This unit typically has three areas:

1. Cleaning area

2. Sterilization area

3. Storage area for sterilized items until needed

If these areas are located within a large space, the airflow should be directed from the storage area to the sterilization area, and then from the sterilization area to the cleaning area.

**7. Ventilation for Service Areas**

Service areas include:

1. Diet food preparation

2. Laundry

3. Mechanical facilities

4. Staff amenities

While these areas may or may not have air conditioning systems, proper ventilation with fresh air is crucial for maintaining hygiene and ensuring a safe environment. Ventilation in these areas should not be limited to exhaust systems alone; there should also be a system for supplying fresh air. This air should be filtered and temperature-controlled.

**8. Ventilation for Laboratories**

To ensure comfort and safety for technicians, laboratories should have air conditioning systems. The presence of fumes, vapors, chemical odors, and heat from equipment all contribute to this need. Determining the most effective, economical, and safe fresh air supply system for laboratories requires study and evaluation. When the amount of fresh air required for the laboratory space is roughly equal to the amount of fresh air needed by the fume hoods, the exhaust system of the hoods can be used to exhaust all the fresh air supplied to the laboratory. If the exhaust from the hoods exceeds the amount of fresh air supplied, additional fresh air should be introduced into the laboratory to ensure adequate air supply for the hoods. VAV (Variable Air Volume) systems for supply and exhaust in laboratories have proven to be successful.

**The Most Important Devices Needed for Cooling, Heating, and Air Conditioning in Different Hospital Sections**

In hospital air conditioning, there are four essential needs:

1. **Precise and Independent Temperature Control** in different sections.

2. **Precise Humidity Control** in various areas.

3. **Controlled Airflow In and Out** of each section, with regulated speed and direction.

4. **Effective Air Filtration** for both incoming fresh air and circulating air.

To meet these four important factors in hospital and medical facility air conditioning systems, various devices are used, with the most significant being:

1. **Chillers**: These devices cool water and send it to air-cooling units inside the building.

2. **Boilers**: These devices heat water (or produce steam) and send it to air-heating units inside the building.

3. **Hygienic Air Handling Units**: Also known as air handlers, these units cool and heat air using cold and hot water from the chiller and boiler. They also function as humidifiers and dehumidifiers to adjust humidity levels as desired, and they filter air to remove contaminants using HEPA, ULPA, and other filters.

4. **Fan Coils**: These units provide local cooling and heating for each room or hall and can also filter air to remove pollutants and reduce humidity when cooling.

5. **Exhaust Fans**: These fans expel air from the building by creating negative pressure and proper airflow.

You can read about the features and structure of each device in other articles.

Author: Engineer Amir Ali Ghiassvand