To answer the question of what an air handling unit (AHU) is, it’s important to understand that any heating, ventilation, and air conditioning (HVAC) system requires a device with a fan to either cool or heat the incoming air to a building or space. This is achieved by passing the air over cooling or heating coils and, if necessary, adjusting the humidity levels by removing contaminants through filters. The AHU, also known as an air handler, provides clean and comfortable air for the building occupants. AHUs typically consist of similar components, which we will review in the following text.

**How Does an AHU Modify Temperature and Humidity?**

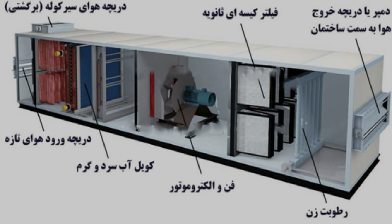

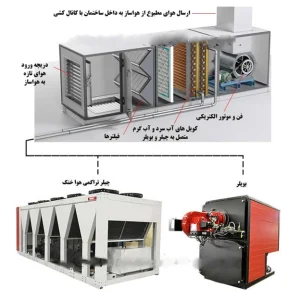

The term “unit” before “air handler” is used because the device is roughly the size of a room and houses all its components within a metal enclosure (as shown in the image below). Inside an AHU, you’ll find a large fan with its accessories, heat exchangers or finned copper coils (similar to a car radiator), air intake and exhaust ducts, sequential filters, humidification and dehumidification components, control system accessories including fan speed controllers, electric actuators for opening and closing air valves, sensors, and electric valves, among others.

**Temperature Reduction in an AHU**

The reduction of air temperature in an AHU occurs as follows: A fluid (usually cold water or refrigerant) circulates through the coils, cooling the copper tubes. The air, which is drawn into the AHU by the fan, is cooled upon contact with the cold tubes and is then directed through ducts to the desired location within the building or space. During the heating process, instead of cold water, hot water flows through the copper tubes to increase the air temperature. AHUs are categorized into two types based on the fluid circulating through the coils: water-based and refrigerant-based (or “D-type” coils). Refrigerants or Freon gas also have the property of either increasing or decreasing the temperature of the copper coils.

It is important to note that cold water is typically generated by a chiller or mini-chiller, and hot water is produced by a package or boiler in the boiler room, then transferred to the AHU system via a pump.

**So far, we have understood how an air handling unit (AHU) changes the temperature of the air, and now we want to understand how it controls the humidity of the air.**

**Adding Humidity to the Air**

To add humidity to the air when needed (especially in hot and dry climates), one of the following methods is typically used:

1. **Injecting Hot Steam**: This method involves injecting hot steam into the air, which increases the amount of water vapor in the air, thereby raising the humidity.

2. **High-Pressure Water Spraying**: Water is sprayed into the air using one or more nozzles, which increases the humidity.

3. **Ultrasonic Method**: In this method, electricity is used with piezoelectric devices to convert liquid water into a gas or water vapor, which is then mixed with the air.

**Removing Humidity**

To reduce the humidity when needed (especially in hot and humid climates), a cold coil and fin method is used. As mentioned, when warm air comes into contact with the cold surface of the coils, the air temperature decreases. Simultaneously, the condensation phenomenon occurs, where the water vapor in the air condenses into liquid droplets on the coil surface. These droplets then drip down and collect in the bottom of the AHU, being expelled through a drainpipe. In humid regions, adding cold coils and fins (which increase the contact surface area) and controlling the cold liquid flowing through them can automatically reduce the humidity to the desired level.

**Summary**

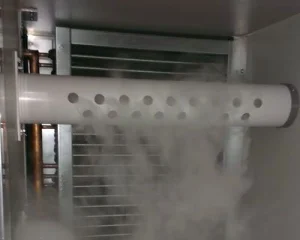

Therefore, an air handling unit is the most suitable ventilation device that not only adjusts and controls air temperature but also automatically regulates the humidity. In the image below, you can see an ultrasonic humidifier (humidity enhancer) integrated into an AHU.

**Other Components of the System and Their Role in Temperature and Humidity Control**

Other components of the air handling system include:

1. **Fresh Air Duct and Damper**: This component is used to bring fresh atmospheric air into the system.

2. **Return Air Duct and Damper**: This allows for the return of air from within the building (circulated air) back into the system.

3. **Conditioned Air Duct and Damper**: This system distributes the conditioned air from the AHU to various partitions within the building through ducts.

4. **Mixing Chamber**: In some AHUs, a portion of the return air from the building, which is exhausted by exhaust fans, is mixed with the incoming fresh air in a designated mixing chamber if required.

5. **Sequential Filters**: Depending on the project’s needs, several types of filters are installed in the AHU. These include:

– **Washable Pre-Filter**: A coarse metal filter that captures large particles like dust and lint.

– **Honeycomb and Electrostatic Filters**: These filters capture soot and allergenic particles.

– **Bag Filters**: These are often used for general filtration.

– **HEPA and ULPA Filters**: High-efficiency filters that capture particles as small as 0.3 to 0.1 microns with up to 99.9% efficiency.

– **Activated Carbon Filters**: These absorb unpleasant odors and harmful gases.

– **UV Lamps**: In some cases, UV lamps are used to eliminate microorganisms in the air, such as bacteria and viruses, through ultraviolet radiation.

Therefore, the AHU not only adjusts the temperature and humidity of the air but also filters it effectively.

It’s important to note that not all of these filters are required together in every case (e.g., in hospital AHUs). For cost reduction, filters are chosen and installed based on the specific needs and level of contamination at the installation site. The image below shows various types of these filters.

**Other Components of the System and How They Assist in Temperature and Humidity Control**

6. **Electric Motor and Centrifugal Fan**: Includes components such as belts, vibration isolators, and the electrical power system. The motor can be either fixed-speed or variable-speed.

7. **Temperature, Humidity, and Airflow Control Equipment**: This consists of a set of sensors and electrical actuators, along with a central processor. It controls the temperature, humidity, and airflow by adjusting the fan speed, opening and closing air dampers, operating and regulating humidity control equipment, and altering the flow and temperature of the fluid in the coils. It interacts with other components of the HVAC system, such as chillers and boilers, to manage these parameters intelligently or manually.

8. **Main Body of the AHU**: This includes the framework supporting the equipment and other structural components.

**Types of Air Handling Units (AHUs) and Their Methods of Temperature and Humidity Control**

1. **AHUs Based on the Presence of Return Air Ducts and Dampers**:

– **Full Fresh Air AHUs**: In some applications, there is no need to recirculate indoor air. Instead, 100% fresh air from the atmosphere is used. This type of AHU, known as a full fresh air AHU, adjusts temperature and humidity as described, but without the return air (circulated air) ducts.

2. **AHUs Based on Enclosure Sealing and High Filtration**:

– **Standard vs. Hygienic AHUs**: Hygienic AHUs, designed for higher cleanliness standards, include the same components but with a more specialized design and additional filters. They maintain temperature and humidity control but with more stringent filtration requirements for applications requiring higher hygiene levels.

3. **AHUs Based on Coil Type**:

– **Cold Water Coils or DX (Direct Expansion) Coils**: AHUs may have either cold water coils or DX coils where refrigerant flows. While both methods change air temperature similarly, cold water coils use water for temperature control, while DX coils use refrigerant.

4. **System Intelligence and Control**:

– **Smart vs. Conventional Systems**: AHUs can be either smart (automatic) or conventional (manual) in their control systems. Smart systems use advanced controls and sensors for automated temperature and humidity management, while conventional systems rely on manual adjustments.

5. **Air Distribution**:

– **Single-zone vs. Multi-zone Systems**: AHUs can distribute air to a single zone or multiple zones within a building, depending on the design and requirements.

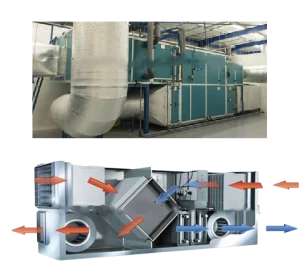

6. **Heat Recovery Capability**:

– **Energy Recovery**: Some AHUs are designed with energy recovery capabilities, which allow them to capture and reuse heat from the outgoing air. This reduces annual energy consumption but increases the initial cost. A diagram of such a system is shown below.

In summary, AHUs can be classified based on various features, including their ability to handle return air, sealing and filtration standards, coil types, control systems, air distribution methods, and energy recovery options. Each type is designed to meet specific needs and operational requirements.

**Applications of Air Handling Units (AHUs)**

Alongside fan coil units, air handling units (AHUs) are among the most commonly used devices for cooling, heating, and air distribution. They are utilized in a variety of settings, including residential, commercial, and office buildings, as well as in industrial, sports, and other specialized facilities. Essentially, AHUs and fan coil units work together to provide a comprehensive heating and cooling ventilation system.

**Features of AHUs Manufactured by Makh HVAC Group**

Having addressed what an air handling unit is and how it adjusts temperature and humidity, we now highlight the key features of AHUs produced by Makh:

1. **Capacity Range**: AHUs are designed and manufactured with capacities ranging from 1,000 CFM to 60,000 CFM as standard. Higher capacities can be designed on a custom or combined basis.

2. **Design Variability**: Available in single-zone and multi-zone configurations, standard and hygienic versions, with or without energy recovery systems, and in both vertical and horizontal designs.

3. **Filter Options**: Utilizes various filters based on project requirements and overall cost considerations, including those mentioned previously.

4. **Frame Construction**: AHU frames are made from standard channel sections and coated with epoxy paint for durability.

5. **Connections**: Equipped with 90-degree reinforced polyamide connections (AROSIO Italy design) that are resistant to sunlight.

6. **Body Construction**: The AHU body is made from 1.25 mm thick Hot Dip galvanized steel, featuring a double-layer construction and a paint coating of 80 to 100 microns.

7. **Engineered Coils**: Coils are designed for high thermal and fluid efficiency, featuring sinusoidal corrugated fins with 8 to 12 fins per inch, and more.

These features ensure that the AHUs manufactured by Makh are robust, efficient, and adaptable to various environmental and operational needs.

**Application of Air Handling Units (AHUs) in Buildings**

The primary function of an air handling unit (AHU) in most applications is to provide fresh air with adequate oxygen levels. Therefore, AHUs are the most suitable device for any building, hall, or warehouse that requires fresh oxygen. They play a crucial role in optimizing the ventilation system.

**When is an AHU Used in Combination with Fan Coils?**

An AHU is used in combination with fan coil units when it is determined that fan coils alone cannot adequately provide controlled-temperature air throughout all areas with sufficient oxygen. In such cases, an AHU is integrated to supply fresh air through ductwork to the required areas, enhancing the overall ventilation.

**Components of an Air Handling Unit (AHU)**

In this article, we will identify the main components of an AHU and explain their roles. We will also discuss the applications of the AHU.

The key components of an AHU are depicted in the image below and include:

1. **Fresh Air Intake Duct and Damper**: Allows for the introduction of fresh atmospheric air into the system.

2. **Return Air Duct and Damper**: Manages the air that is recirculated from inside the building.

3. **Supply Air Duct and Damper**: Distributes the treated air from the AHU to various parts of the building through ductwork.

4. **Mixing Chamber**: In some AHUs, a portion of the return air is mixed with fresh air in a designated mixing chamber before being processed further.

5. **Filters**: These remove particulates and contaminants from the air. The AHU may include various filters, such as pre-filters, electrostatic filters, bag filters, HEPA, ULPA, activated carbon filters, and UV lamps, depending on the specific requirements of the project.

6. **Electric Motor and Fan**: A centrifugal fan, powered by either a fixed or variable-speed motor, circulates air through the system. This includes components like belts, vibration isolators, and electrical connections.

7. **Temperature, Humidity, and Airflow Control Systems**: Includes sensors, actuators, and a central processor that manages the fan speed, damper positions, humidity control equipment, and interaction with other HVAC devices like chillers and boilers.

8. **Main Unit Frame**: The structural framework that supports all the AHU components.

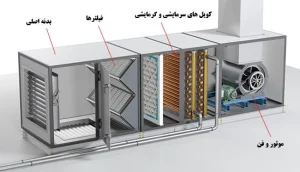

**Important Components of an AHU**:

The most important components of an AHU are illustrated in the image below and include the elements listed above. Understanding these components helps in comprehending how the AHU operates and its role in maintaining optimal indoor air quality and comfort.

**1. Cooling Coil**: This coil contains cold water or refrigerant supplied by the chiller, which cools the air passing over it.

**2. Heating Coil**: This coil contains hot water or steam supplied by the boiler, which heats the air passing over it.

**3. Filters**: These include various types of filters such as bag filters, washable filters, HEPA filters, etc., tailored to the specific needs of the project.

**4. Main Body**: The main body and cover of the AHU are typically constructed from an aluminum frame with double-walled panels made of galvanized steel. The panels are insulated internally with thermal and acoustic insulation.

**5. Motor and Fan Assembly**: The AHU fan is usually a centrifugal type and is dependent on air pressure and volume. It can be direct-driven or belt-driven.

**6. Humidity Control Equipment**: This equipment precisely regulates the humidity of the air passing through the AHU.

**7. Electrical and Mechanical Control Equipment**: These are among the most critical components of the AHU, managing the operation and settings of the unit.

**8. Three Aluminum Dampers**: One damper is for air exhaust, while the other two are for fresh and return air intake.

**Key Roles of AHU Components**

The primary role of the components of an AHU is to regulate air humidity and temperature and distribute air at appropriate speeds and directions. Essentially, the AHU brings in outside air, conditions it by adjusting temperature, humidity, and filtration, and then delivers it as fresh air into the building. Additionally, a portion of the return air from inside the building is mixed with the fresh air. The proportion of return air (recirculated air) to fresh air depends on the specific requirements and usage of each project. In the image below, you can see the AHU components, including a fresh air intake damper on the left and a return air damper at the bottom (left side), which form a mixing chamber.

**Operation of an Air Handling Unit (AHU) Connected to a Chiller**

A chiller is a cooling device that can be connected to an AHU in two ways:

1. **Indirect Connection**

In this method, the chiller reduces the temperature of water in a circuit. This chilled water is then transferred to the AHU via piping and pumps, where it flows through the AHU’s coils, thereby lowering the temperature of the air passing over the coils (which is blown into the AHU by a fan).

2. **Direct Connection**

In this method, known as a “rooftop package unit,” there is no need to chill water and send it to the AHU. Instead, refrigerant gas (such as Freon) flows directly through the AHU’s coils, reducing the temperature of the passing air.

**Applications of Air Handling Units (AHUs)**

An AHU can be used in two main ways across various applications:

1. **AHU Used in Conjunction with Fan Coil Units**

The use of AHUs is not limited to a small segment of HVAC systems. When combined with fan coil units, AHUs serve as a source of fresh air, air purifier, humidity and temperature controller, and air distributor through controlled channels. Some common applications include:

– **Office Buildings**

– **Commercial Buildings**

– **Residential Buildings**

– **Hospitals** (hygienic or sanitary type)

In this design, each room or section of the building has one or more fan coil units to independently control the room’s air. Alongside this, one or more AHUs provide fresh air throughout the building via ducts. This combination allows occupants to adjust the temperature of their room with the fan coil unit and turn it off if ventilation is not needed, thus saving energy. Meanwhile, the AHU continuously supplies fresh and conditioned air throughout the building.

2. **AHU Used Independently**

In this case, AHUs are used without fan coil units, as the space being conditioned (for example, in applications mentioned below) is typically one large area rather than divided rooms. Some key independent AHU applications include:

– **Industrial Warehouses**

– **Sports Halls**

– **Conference Halls, Cinemas, Restaurants, etc.**

In such designs, AHUs alone are used to supply and distribute fresh air in large, open spaces.

Author: Engineer Amirali Ghiassvand