The Function of Compressors in Chillers

The role of the compressor in a chiller is to compress the refrigerant cycle. Based on the shape and structure of the components of the compressor, they are generally divided into four categories. In this text, we will thoroughly examine and compare four commonly used types of chiller compressors.

**Types of Chiller Compressors and Refrigeration Devices**

There are mainly four types of compressors used in compression chillers and other refrigeration devices:

1. **Piston Compressors (Piston Type) or Reciprocating Compressors**

2. **Scroll Compressors (Scroll Type)**

3. **Screw Compressors (Screw Type)**

4. **Centrifugal Compressors (Centrifugal Type)**

These compressors are driven by an electric motor (electromotor), internal combustion piston engine, steam engine, or gas turbine.

**1. Piston Compressors (Piston Type) or Reciprocating Compressors**

Piston or reciprocating compressors are among the most widely used compressors in the refrigeration industry and are divided into three categories: Hermetic, Semi-Hermetic, and Open.

– **Hermetic**: The term “hermetic” means that the casing (shell) is welded and completely sealed, making access to the cylinders and inspection impossible. These are used in lower capacities.

– **Semi-Hermetic**: This type has a casing that can be opened for maintenance and is more commonly used in medium capacities.

– **Open**: In open compressors, there is no casing. The electromotor and gearbox are installed externally (as shown in the image below). This type of compressor is now used for very high capacities and applications where the power exceeds one megawatt, being the only viable option. In all three systems, the refrigerant gas is compressed by the reciprocating motion of the piston within the cylinder.

—

The operating noise of this type of compressor is higher compared to other types. However, if the chiller is installed in a mechanical room or an exterior space such as on the roof, the operating noise will not be transmitted into the building. This type of compressor has a simple structure and can be repaired if it becomes worn out. Reciprocating compressors are more commonly used in tropical climates (hot and humid areas) like the southern regions of the country because they can withstand high pressures resulting from increased ambient temperatures. In contrast, if other types of compressors, such as scroll or screw compressors, are used in these regions, they can suffer severe damage after a short period due to their inability to handle high temperatures and pressures. Unless special scroll or screw compressors designed for tropical regions are used. A chiller with a reciprocating compressor is referred to as a reciprocating compression chiller. An example of this type is shown in the image below.

2. **Scroll Compressor**

A scroll compressor consists of two spiral-shaped pieces, one stationary and the other moving, which is connected to the motor. The refrigerant is compressed as the moving spiral rotates around the stationary spiral, moving towards the center. Scroll compressors are widely used in light to medium commercial and residential air conditioning systems, such as chillers, mini-chillers, cooling and heating heat pumps (GHP), VRF systems, split systems, ducted splits, and others. Their capacity typically ranges from 3 to 120 kilowatts and they are used in high-capacity applications in a combined form (by coupling multiple compressors together and creating multiple circuits). Among its advantages are its very low noise level and smooth, vibration-free operation. These compressors are typically used with variable-speed inverter motors and brushless DC motors. A chiller with a scroll compressor is referred to as a scroll chiller.

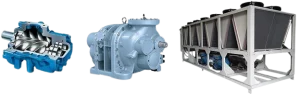

3. **Screw Compressor**

Among the types of compressors used in compression chillers and other refrigeration equipment, piston, screw, and scroll compressors are the most commonly used. Screw compressors consist of two helical rotors, also known as screws. As the rotors rotate, the refrigerant is drawn in through the inlet between the two rotors and compressed. These compressors require extensive lubrication due to the specific geometry of the rotors and are designed with either oil-injected or oil-free lubrication systems. In low-load conditions (Part Load), where the compressor operates for the majority of its time under low load, a sliding valve mechanism is installed between the inlet and the compressor chamber. This mechanism, controlled automatically, allows for continuous adjustment of the refrigerant flow, significantly improving efficiency when the compressor is operating at reduced capacity. Screw compressors have a higher capacity compared to scroll compressors and are typically used in high-capacity chillers. Notable manufacturers of screw compressors include Bitzer from Germany and Hanbell from Taiwan. A chiller with a screw compressor is referred to as a screw chiller.

4. **Centrifugal Compressor**

A centrifugal compressor consists of a casing, a shaft, and an aluminum impeller (fan). The refrigerant enters the central part of the impeller and is then thrown outward by centrifugal force due to the rotation of the impeller. This kinetic energy is converted into pressure energy in the diffuser. The capacity of a centrifugal compressor can be adjusted by using vanes that change the angle of refrigerant entry into the center of the impeller. These compressors typically operate with R410A refrigerant and are used in applications with low compression ratios and high cooling capacities where the chiller operates at or near maximum capacity for most of its time. This is because if a centrifugal chiller operates under low load, the efficiency decreases significantly due to the reduced speed of the connected electric motor. Therefore, this type of compressor is used in building, commercial, and industrial applications where the chiller needs to operate continuously and at full capacity. A chiller with a centrifugal compressor is referred to as a centrifugal chiller.

Author: Engineer Amir Ali Ghiasvand