What is a Hygienic (Cleanroom) Air Handling Unit?

In this comprehensive article, we aim to understand the components, operation, and features of hygienic (cleanroom) air handling units, which are used in environments such as hospitals and cleanrooms, and to explore the standards involved in their design and construction.

First, we will address the question of what a hygienic (cleanroom) air handling unit is, and then we will look at the types of filters used in its structure, as well as other characteristics and standards that must be adhered to in its design and production.

What is a Hygienic (Cleanroom) Air Handling Unit?

A hygienic or cleanroom air handling unit is structurally very similar to a standard air handling unit, with the primary difference being its construction for achieving 99.99% cleanliness of the incoming air through specialized filtration and advanced sealing. Hygienic air handling units are widely used in hospitals, laboratories, pharmaceutical companies, cleanrooms, food industries, data centers, electronics and semiconductor industries, aerospace industries, and some chemical (industrial) applications where contaminants such as suspended particles, allergens, pathogens, microorganisms, and more should not be transferred from one location to another through the air. Additionally, hygienic industrial air handling units and greenhouse air handling units are used in certain industrial and agricultural applications, respectively. The term “hygienic” reflects the device’s importance in critical HVAC systems for sensitive areas like hospitals and cleanrooms.

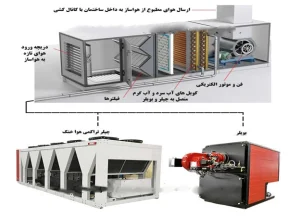

Operation of a Hygienic Air Handling Unit

As mentioned, hygienic air handling units have a very similar structure to standard units but feature advanced filtration and sealing systems. The overall system often includes a chiller and a boiler: the chiller cools water and the boiler heats it. This warm and cold water flows through the copper coils of the air handling unit, adjusting the temperature of the air passing through the device. Various types of filters are used inside the unit based on the requirements.

The system forms a complete HVAC solution where air enters the air handling unit, undergoes processes such as filtration, temperature adjustment, and humidity control, and then exits as clean air with controlled humidity and temperature, which is distributed to the desired points via ductwork. The question then arises: besides the components and processes used in non-hygienic air handling units, what additional features and standards does a hygienic (cleanroom) air handling unit have?

#### Features and Specifications of Hygienic Air Handling Units

1. **Specifications**: The specifications of a hygienic air handling unit are similar to those of a standard unit, consisting of heating and cooling coils, fans, moisture control equipment, and input and output ducts. However, filtration is typically performed in three stages:

– **First Stage**: The air passes through a metal mesh filter to prevent large solid particles from entering the unit.

– **Second Stage**: The air goes through bag filters, which remove up to 95% of contaminants.

– **Third Stage**: The air is further purified by HEPA and ULPA filters, which remove 99.99% of pollutants (particles between 0.1 to 0.3 microns in size), making these units suitable for sensitive environments such as hospitals.

This 99.99% removal rate is the minimum level achieved by these filters.

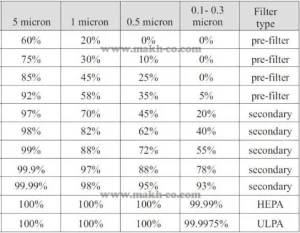

2. **Filtration Percentages**: The table below shows the filtration percentages of the air handling unit filters based on particle size (in microns). Pre-filters (coded G1 to G4) can filter particles up to 5 microns with varying efficiencies, while secondary or bag filters (coded F5 to F9) are capable of filtering particles down to 1 micron with high efficiency.

For example, a G3 pre-filter can remove 85% of particles up to 5 microns and 45% of particles up to 1 micron. An F9 bag filter can remove 99.99% of particles up to 5 microns and 98% of particles up to 1 micron.

HEPA and ULPA Filters

HEPA filters are designated with standard codes from H10 to H14, while ULPA filters are coded U15 to U17. ULPA filters can filter particles ranging from 0.1 to 0.3 microns with an efficiency of up to 99.9975%. The use of these filters is one of the key features and standards in cleanroom air handling units, hospital air handling units, and generally all types of hygienic air handling systems.

Here is an image of HEPA and ULPA filters with efficiency ranging from 99.99% to 99.9999%:

2. The body of the unit is made entirely of stainless steel to prevent corrosion, which can be a source of contamination. Additionally, all metallic parts must be made from rust-resistant materials or coated with anti-corrosion layers. Non-metallic materials used in the device should be selected in a way that prevents the growth of microorganism colonies. During the manufacturing process, none of the components should use hazardous or odorous chemicals. Adhering to these requirements in the design and construction of hospital air handling units, cleanroom air handling units, and similar systems is mandatory and must comply with existing standards.

3. The structure (framework) of the unit is made from aluminum profiles and sealed with polyamide strips to prevent any air leakage. These aluminum profiles are connected using polyamide fittings to create a sturdy and airtight framework.

4. Since sharp and angled corners inside the body are prone to the accumulation of contaminants, no sharp or angled corners should be designed. All corners must be rounded. For example, if you compare the internal structure of a cleanroom air handling unit with a non-hygienic type, you’ll see that all corners are rounded, and there are no right angles where columns and panels connect.

5. The surface between the body and the doors and dampers must be well-sealed to prevent any unfiltered air from entering the unit.

6. Coils are usually made of copper with aluminum fins. Beneath the coil, there is a tray made of aluminum or stainless steel with a gentle slope to collect and drain the water droplets that form on the coil, preventing the accumulation of contaminants. If corrosive chemicals are present in the ambient air, the fins should also be made of copper to enhance the coil’s resistance to corrosion. In any type of air handling unit (whether hygienic, like hospital air handlers, or non-hygienic), some of the moisture in the air condenses into water droplets upon contact with the cooling coils. These droplets must be collected and drained. One of the key features and standards for hygienic (clean) air handling units is that all parts should be designed with sliding mechanisms and rails for easy removal and internal cleaning.

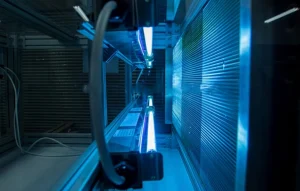

7. UV lamps are installed downstream of the coils to prevent the growth and proliferation of fungi, parasites, and bacteria. Typically, each UV lamp is equipped with a reflector to ensure that its radiation is effectively focused on the coils and the water collection tray. Additionally, the framework on which the lamps are mounted should be designed with a sliding mechanism to facilitate easy removal and cleaning during maintenance. In some cases where more thorough sterilization is required, ozone generators are also used.

8. The fan used in hygienic air handling units, such as those for clean rooms and hospitals, should be of the backward centrifugal type. This is because the filters create significant resistance to the airflow (high static pressure), and backward centrifugal fans, due to their specific blade design, can generate a large airflow volume. In contrast, forward centrifugal fans are used in conventional (non-hygienic) air handling units. While backward centrifugal fans provide higher airflow, they have lower efficiency compared to forward centrifugal fans.

**What Standards Must Hygienic Air Handling Units (AHUs) Adhere To?**

Every hygienic air handling unit (AHU) must be designed and manufactured according to international standards. These standards are crucial because, for example, in hygienic environments such as hospital operating rooms, the hospital AHU must consistently provide air that is uniform, with appropriate temperature and pressure, free of any contaminants and live microorganisms. Simultaneously, the exhaust fans must effectively remove the air from the environment, ensuring a constant flow of clean air with positive pressure, thereby preventing contamination from outside to inside sensitive rooms and vice versa. The most important international standards for the construction of hygienic AHUs include:

1. **EN 1886 Standard – Building Ventilation Systems and Mechanical Performance:**

This standard specifies the mechanical properties for the design and construction of a central air conditioning system, such as AHUs, including installation and maintenance guidelines. For example, it covers the maximum allowable air leakage from different sections of the hygienic AHU and its thermal insulation.

2. **VDI 3803 Standard – Technical and Structural Principles of Air Conditioning Systems:**

This standard defines the technical and structural conditions of a central air conditioning system. It includes specifications for various types of filters.

3. **VDI 6022 Standard – Hygienic Air Conditioning Systems:**

This standard outlines the hygienic conditions required for a central air conditioning system and AHUs. For instance, it specifies that corners and edges of the internal walls should be rounded to prevent the accumulation of water or dust, all surfaces should be flat, the lower panels should be made of stainless steel with a proper slope for water drainage, and all doors and components should be designed for easy assembly and disassembly for internal cleaning.

4. **EN 13053 Standard – Classification and Performance of Air Handling Units:**

This standard sets requirements for non-residential air handling systems with airflows greater than 250 cubic meters per hour. It includes parameters such as airflow velocity, energy consumption, and energy recovery.

**Features and Standards of Hospital AHUs:**

A hospital AHU is essentially a hygienic AHU that adheres to the aforementioned standards. In addition to these standards, there is another important standard for healthcare facilities and hospitals, known as **DIN 1946**, which must be considered in the design and construction of hospital AHUs.

**What Characteristics and Features Does a Clean Room Air Handling Unit Have?**

All the characteristics and standards mentioned for designing and producing hygienic air handling units (AHUs) must also be applied to clean room AHUs, commonly referred to as clean room units. However, clean rooms are categorized based on their sensitivity to the ingress of contaminants, and this categorization impacts the type of filtration required.

**Key Points for Clean Room AHUs:**

1. **Adherence to Hygienic Standards:**

– The same hygienic standards and features outlined for hygienic AHUs apply to clean room AHUs. This includes advanced filtration systems, stainless steel construction, smooth interior surfaces, and rigorous sealing to prevent contamination.

2. **Filtration Requirements:**

– Clean rooms are classified into various categories based on the level of cleanliness required, which dictates the type and efficiency of filters used. The level of filtration needed is determined by the specific cleanliness class of the clean room, as defined by standards such as ISO 14644.

– Higher filtration efficiency often results in higher costs for the clean room AHU. For instance, while HEPA filters might be sufficient for some applications, others may require ULPA filters for the highest level of cleanliness.

3. **Filter Selection:**

– The selection of filters should align with the specific needs of the clean room. It is not always necessary to use ULPA filters in every situation; instead, filters should be chosen based on the environment’s sensitivity to contaminants.

– The filtration efficiency should be matched to the clean room’s classification to ensure the required level of air purity is achieved.

In summary, while clean room AHUs must meet the stringent requirements of hygienic AHUs, the choice of filters and the overall design will depend on the clean room’s specific classification and contamination control needs. This approach ensures both effective contamination control and cost efficiency.

**How Is the Price of Hygienic (Sanitary) Air Handling Units Determined?**

The price of hygienic (sanitary) air handling units is determined based on several factors, including the type of filters used, the installation of humidifiers or dehumidifiers and humidity control systems, whether the dampers (air inlets and outlets) are electric or not, and the material of the coil fins (aluminum or copper).

**Where Are Hygienic Air Handling Units Most Commonly Used?**

1. Pharmaceutical facilities

2. Sterilization centers

3. Hospitals and laboratories

4. Clean rooms (both sanitary and industrial)

5. Certain sensitive chemical and electronic industries

**Why Are Hygienic Air Handling Units Typically Designed as Full Fresh Air Systems?**

Full fresh air design means that all the air entering the unit is sourced from outside and no return air is used. The reason for this is that in certain environments (such as operating rooms), it is better to expel all the air in the room, which may contain various viruses and bacteria, to the outside rather than returning it to the air handling unit.

**Author: Engineer Amirali Ghiassvand**