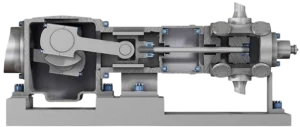

The most important component used in a chiller is its compressor. A chiller whose compressor is a reciprocating type (cylinder and piston) is called a reciprocating or impact compression chiller. A cutaway view of a reciprocating chiller is shown in the figure below. To understand its function, we will first describe the work cycle and its components, and then we will discuss its advantages and disadvantages, which will be our guide in choosing a suitable chiller.

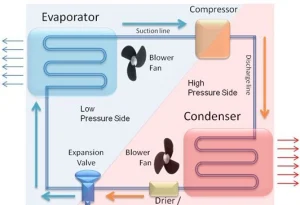

After the expansion valve, the liquid goes to the evaporator (the evaporator is also a winding coil) and this time by taking the heat of the environment around the coil, it turns into a gas and goes back to the compressor until this cycle is called the refrigeration cycle. to continue These are the most important components that make up an impact chiller (reciprocating), which in the following, while getting to know them in detail, we will also examine the disadvantages that these compressors create in the chiller.

The main components of the reciprocating compression chiller and its performance. The main components in the reciprocating compression chiller are: 1 . The reciprocating compressor of the shock chiller is a positive displacement type compressor that keeps the volumetric flow relatively constant in a wide range of pressure ratios. Three types of compressors are usually used in reciprocating chillers: 1. Closed or hermetic compressor for chillers up to 25 tons of refrigeration 2. Semi-closed compressor for chillers up to 200 tons of refrigeration 3. Open compressor with direct connection to the drive for high capacity chillers in closed or hermetic type, the motor and compressor are directly coupled and placed inside a completely closed and sealed chamber with respect to the atmospheric air. In the open type, the motor and compressor are each placed in their own separate compartments. In general, the open type has a longer life, requires less maintenance and has a higher efficiency. Hermetic type is mostly used in low capacities. Of course, open compressors are usually more expensive than closed compressors. The components that make up these compressors are the same, and only the arrangement of the electric motor and the compressor are different. Compared to other compressors, these compressors cause disadvantages in reciprocating compression chillers, which we will mention at the end of this article. 2 . Reciprocating compression chiller condenser These condensers can be air-cooled or water-cooled. Water-cooled condensers may be chosen because they are cheaper than the two-tube or shell-and-coil type, or because they are denser and less bulky than the shell-and-tube type. Also, the use of air-cooled condensers (fan condensers) is as common as the shell and tube type. A chiller whose condenser is water-cooled or shell and tube is called a water-cooled (blue) chiller, and a chiller whose condenser is air-cooled or fan-cooled is called an air-cooled (air) chiller. The following figure shows the air-cooled type with its main components. 3 . Evaporators, which are also called evaporators, are usually of the shell and tube type, where the refrigerant evaporates when it passes through the tubes by absorbing the heat of the water around the tubes, and at the same time, the water that heats up It loses itself and becomes extremely cold, and this cooled water is sent with a pump for the required uses. 4 . The expansion valve of this valve adjusts the amount of refrigerant flow and pressure from the condenser to the evaporator in such a way that the refrigerant sucked by the compressor must be in a gaseous state and does not enter the compressor in liquid form. Excessive evaporation of the refrigerant should also be avoided because it will reduce the capacity of the device.