The main objective of this article is to understand the concept of “What is a screw chiller?” and, while recognizing its details and features, to explore the advantages of a screw compression chiller compared to other types of chillers.

**What is a Screw Chiller and What Advantages Does it Have Over Other Chillers?**

The term “screw chiller” comes from the fact that its most important component, the compressor, is of the screw or helical type. The operation of a screw compression chiller involves the compressor compressing the gaseous refrigerant and sending it through the cooling circuit to other components such as the condenser, expansion valve, and evaporator. This process continuously cools another fluid, such as water, through a cyclical process.

In the diagram below, the main components of a water-cooled screw chiller with a shell and tube type water-cooled condenser are shown. In the first stage, the refrigerant is compressed by the screw compressors and sent through copper pipes to the condenser. Condensers can either be water-cooled (typically shell and tube type) or air-cooled (cooled by fans). The condenser is where the refrigerant loses heat and changes from a gaseous phase to a liquid phase. After passing through the expansion valve, it enters the evaporator. The evaporator is where the water is cooled; the refrigerant absorbs heat from the water, lowering its temperature, and this cycle continuously repeats.

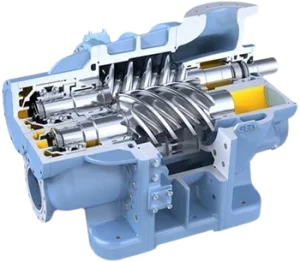

The structure of a screw compression chiller is quite similar to other types of compression chillers (such as scroll, piston, and centrifugal chillers); the key difference lies in the type of compressor used. To compare screw chillers with other types and understand their advantages, one must examine their compressors. For instance, the image below shows a water-cooled screw compression chiller (with a water-cooled condenser) equipped with a screw compressor from Bitzer.

Bitzer, a German company, and Hanbell, a Taiwanese company, are among the leading designers and manufacturers of screw compressors globally. The image below shows examples of chillers being constructed at our factory, equipped with screw compressors from Bitzer and Hanbell.

To understand the features of screw chillers, it’s essential to examine the characteristics of a screw compressor. Here, we’ll discuss the advantages and disadvantages of screw compressors.

**Features of Screw Compressors**

1. **Construction**: Screw compressors mainly consist of two rotating rotors (as shown in the image below). When one of these rotors is driven by an electric motor or other power source, the refrigerant is compressed between the two rotors.

2. **Lubrication System**: The lubrication system of these compressors is relatively complex. A decrease in oil levels can gradually lead to damage of components and bearings. Therefore, it is crucial to monitor and control oil pressure and levels regularly, as specified in the manufacturer’s catalog.

3. **Type and Operation**: Screw compressors, like reciprocating or piston chiller compressors, are positive displacement devices. They are available in single-screw and twin-screw types and can be categorized based on lubrication as either oil-free or oil-injected.

4. **Twin-Screw Compressors**: Twin-screw compressors, which use oil injection, have higher efficiency under medium-load conditions. They can operate at compression ratios up to 30:1. Their capacity can be adjusted according to the required load, and capacity control is managed by a sliding valve that alters the compression ratio to maintain optimal compressor performance. These compressors are typically available in capacities over 20 tons of refrigeration. The image below shows a cross-sectional view of a screw compressor.

**Advantages of Screw Compressors Compared to Other Compressors**

1. **Low Noise and Vibration**: Due to the unique structure and spacing between the two rotors, screw compressors produce less noise and vibration compared to piston-cylinder compressors.

2. **Smooth and Continuous Gas Flow**: The refrigerant gas flow from the compressor is steady and uniform, without fluctuations, eliminating one of the main causes of noise and pulsation.

3. **Capacity Control**: Screw compressors offer continuous capacity control, ranging from 10% to 100% of the total capacity.

4. **Long Service Life and High Reliability**: These compressors are known for their durability and reliability.

5. **Low Discharge Temperature**: They operate with lower discharge temperatures.

6. **High Volumetric Efficiency**: Screw compressors provide high efficiency in terms of volumetric performance.

7. **Smaller Size and Compact Design**: They are more compact compared to reciprocating compressors.

8. **No Damage from Liquid Reversion**: Screw compressors are designed to handle liquid refrigerant without damage.

9. **Simpler and More Cost-Effective Maintenance**: Due to fewer sliding parts, major repairs are simpler and less costly.

**Key Advantages of Screw Compression Chillers:**

1. **Smaller Size and Lower Weight**: Screw chillers are more compact and lighter compared to other systems.

2. **Quiet Operation**: They operate very quietly with minimal noise and vibration compared to other compressors, including piston-cylinder types.

3. **High Efficiency at Both Full Load and Part Load**: Screw chillers maintain high efficiency in both full load and part load conditions, unlike centrifugal chillers, which are efficient only at full load.

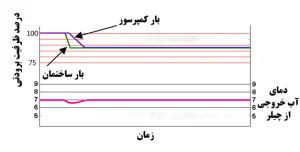

4. **Continuous Capacity Control**: Capacity control in screw compressors is continuous rather than stepwise. For a single-screw chiller, capacity can be precisely and continuously adjusted between 25% and 100% of the total capacity. For a dual-screw chiller, capacity can be controlled between 12.5% and 100%. This precise, non-stepped control allows for accurate temperature regulation of the chilled water output, avoiding temperature fluctuations. The graph below shows how the compressor and chiller load adjust immediately with changing cooling loads, keeping the output water temperature stable. This capability is a significant advantage of screw chillers, providing both stable water temperatures and significant energy savings.

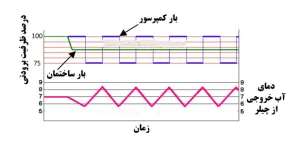

If capacity control is stepwise (non-continuous), the load of the compressors and chiller will not match the cooling load required by the building (or industrial equipment). As a result, the chiller will operate with either too much or too little load. For example, as shown in the diagram below, when the cooling load required by the building decreases from 100% to around 87% (green line), the load of the compressors and chiller fluctuates between 75% and 100% (blue line). This occurs because the chiller uses four fixed-speed compressors with no capacity adjustment. Each compressor operates in turn (25% to 25%) and when the cooling load reaches 87% of the chiller’s total capacity, all four compressors briefly activate, causing the chiller to operate at 100% capacity. When the temperature of the water exiting the chiller drops below 6°C, one of the compressors automatically shuts off, reducing the load of the compressors and chiller to 75% of the total capacity. As a result, the temperature of the water exiting the chiller increases to 8°C after a short period, causing the fourth compressor to turn back on, raising the chiller’s total capacity back to 100%, and the water temperature decreases back to 6°C.

**Diagram of Water Temperature Fluctuation from a Chiller Equipped with Four Fixed-Speed Scroll or Piston Compressors:**

**Now that we have answered the question “What is a screw chiller?” in general and reviewed its advantages compared to other chillers, it raises the question of why screw compressors are not used in all chillers.**

The answer is that there are multiple parameters involved in choosing the type of compressor, and even screw compressors themselves are divided into various types designed for specific environmental conditions. These parameters include the high capacity of these compressors, the need or lack thereof for a chiller to have 2 or 4 circuits, cost, and the after-sales service of the compressor providers (typically Hanbell and Bitzer). For example, screw compressors are not recommended for low capacities and are considered for capacities higher than 100 tons of refrigeration. For capacities below 100 tons, more cost-effective and lower-maintenance compressors, such as scroll compressors, are generally recommended. Due to the advanced technology required to manufacture screw compressors, their cost is naturally higher compared to other types. It is recommended that the choice of compressor be based on the specific project and its characteristics and should be made by specialists in the field.

**One application of screw compression chillers can be in cooling industrial machinery.**

**In the Iranian chiller industry, for what tonnage are screw chillers typically used?**

In the chiller industry, screw chillers are generally used for capacities above 50 tons of refrigeration or more commonly above 100 tons of refrigeration.

**What is the main problem with using screw compressors in chillers?**

The main issue with screw chillers is their higher cost compared to reciprocating and centrifugal chillers. However, it is important to note that reciprocating and centrifugal compressors also have their own drawbacks. For example, centrifugal chillers are less efficient and effective at low load conditions.

**What type of refrigerant is typically used in screw chillers?**

Screw chillers typically use refrigerants such as HCFC-22 and HFC-134a.

**Author: Engineer Amir Ali Ghiathvand**