The term “scroll” refers to the type of compressor used in a chiller (scroll compressor). Scroll chillers are typically used in low to medium tonnage applications, while for higher refrigeration tonnages, screw, piston, or centrifugal chillers are used. Scroll chillers usually incorporate several scroll compressors in combination to increase their capacity.

Scroll chillers, like other compression chillers, operate based on the vapor-compression refrigeration cycle and are also referred to as scroll compression chillers. Based on the type of condenser, there are two types of scroll chillers: water-cooled scroll chillers (with a water-cooled condenser) and air-cooled scroll chillers (with an air-cooled condenser).

To understand their structure and the advantages they have over other devices, stay with us till the end. The structure of a scroll chiller is shown below, illustrating the general structure of an air-cooled chiller (with an air-cooled condenser where the refrigerant is cooled by fans). These chillers are equipped with scroll-type compressors, which continuously reduce the water temperature in the evaporator section. This chilled water is used for applications such as building air conditioning or cooling an industrial machine.

To control the operational capacity of scroll chillers (based on the consumer’s needs), they are typically designed in a modular fashion. For example, consider a 40-ton cooling capacity chiller. Instead of using a single 40-ton compressor, two 20-ton compressors or four 10-ton compressors can be used. A separate refrigeration circuit can be designed for each compressor (or pair of compressors). This allows the system to operate only one circuit when only 25% (or less) of the total cooling is required, leaving the other compressors off. This results in increased equipment lifespan and significant energy savings. If, for instance, 60% of the total cooling is needed, three compressors will operate while one remains off.

The advantages of a modular scroll chiller over a non-modular one are significant, such as reduced power consumption and increased component lifespan. While modular design slightly increases the chiller’s price, the benefits far outweigh this small cost increase, making this upgrade highly recommended.

It is worth noting that the components and structure of scroll chillers are similar to other types of compression chillers, with the only difference being the compressor.

What are the advantages of a scroll compressor?

The scroll compressor consists of two scrolls: one fixed and one movable, which fit into each other to compress the refrigerant. The working principle of the scroll compressor is that the movable scroll moves eccentrically in a circular motion. The refrigerant enters from the outer part (the suction chamber) where the space between the two scrolls increases. Gradually, it is compressed towards the center of the scrolls, increasing its pressure and temperature. Finally, it exits from the center (the discharge chamber). The internal structure of a scroll compressor is shown in the diagrams below.

Other benefits of scroll compressors include:

– High efficiency at predefined compression ratios and during low-load operation,

– Easy and low-cost maintenance.

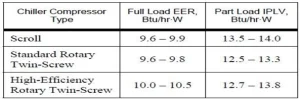

The table below compares the efficiency of scroll compressors with standard rotary twin-screw compressors and high-efficiency rotary twin-screw compressors. It highlights the higher efficiency of scroll compressors, especially in part-load conditions.

Since compressors typically operate in part-load conditions for about 90% of their lifespan, part-load efficiency is more important than full-load efficiency.

The content you provided references the article titled “High Efficiency Compression for Commercial and Industrial Application”

Therefore, the main advantages and superiorities in the structure of scroll chillers are as follows:

1. **Less vibration and noise during operation** compared to screw and piston types.

2. **Optimized performance in part-load conditions** (due to higher efficiency), leading to reduced power consumption.

3. **More affordable price for scroll compressors** compared to screw compressors.

4. **Longer lifespan** due to the low-wear structure of scroll compressors.

Today, variable-speed drive technology or inverters (variable-speed motors) are used for compressor rotation, allowing the compressor to adjust its speed according to the cooling demand. This prevents the compressor from always running at full capacity, significantly reducing power consumption. However, adding an inverter can substantially increase the price of a scroll chiller. It is often recommended to design the scroll chiller in a modular fashion instead of using an inverter, as this approach provides similar benefits with a minimal price increase.

**Does a scroll chiller consume less power compared to screw and piston chillers?**

Yes, exactly. This is because scroll compressors, especially in part-load conditions, have higher efficiency compared to screw and piston compressors, which results in lower power consumption under similar conditions. However, this factor alone is not sufficient to decide on the type of compressor.

**What brand of scroll compressors is most commonly used in Iran?**

In Iran, Copeland scroll compressors (from Thailand and China) and Danfoss scroll compressors are the most commonly used, primarily due to their widespread distribution and after-sales service.

Author: Eng. Amirali Ghiassvand